Australia’s Smart Building Revolution

Australia’s construction sector is facing a perfect storm. Rising demand, shrinking labour, and mounting pressure to decarbonise. A recent article from prefabAUS laid out a compelling roadmap for transformation. At OFFSITE, we believe this isn’t just a vision, it’s a call to action.

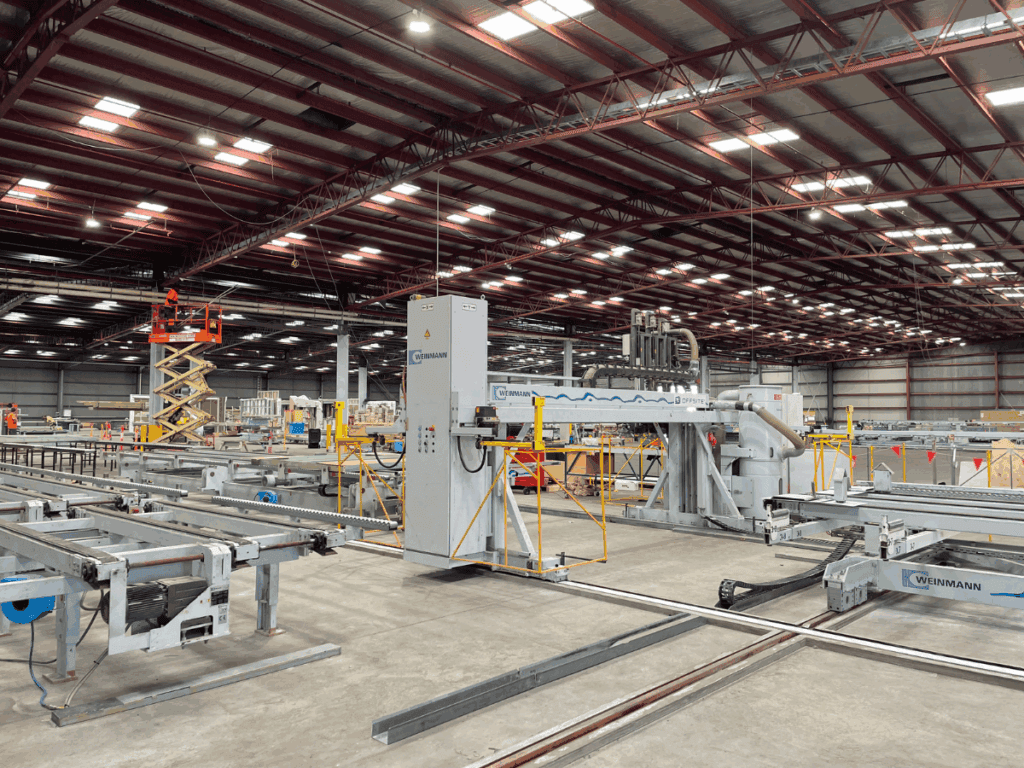

Smart Building, powered by offsite prefabrication and Industry 4.0 manufacturing, offers a scalable, high-performance solution to the challenges we face. The potential? A conservative $9 billion in annual economic benefits for Australia by 2033.

But the real value lies in what this shift will unlock: housing affordability, industrial innovation and a pathway to net zero.

We’re not talking about replacing traditional construction, but complementing it – adding speed, precision, and sustainability where it matters most.

The Government’s National Housing Accord target of building 1.2 million homes by 2030 is the catalyst we need. Smart Building can deliver at scale, with quality and cost-efficiency that conventional building methods can’t match.

Strategic procurement is the key

International leaders like Singapore and the UK are already mandating prefabrication in public projects. Australia must follow suit. Traditional procurement frameworks don’t support the scale, efficiency, and sustainability of Modern Methods of Construction (MMC).

Smart Building is also central to Australia’s reindustrialisation

As global demand for low-carbon materials surges, Australia’s renewable energy advantage positions us to lead in responsible steel, aluminium, mass timber, and low-carbon concrete. Smart Building creates the demand driver for these materials while building these industries locally. Without a strategic shift, we risk defaulting to imported solutions. Missing the opportunity to build a resilient, high-tech, Australian Smart Building industry.

At OFFSITE, we’re ready to be part of the Smart Building industry revolution. The question is: will Australia seize this moment?