Our New Hundegger SC480 Speed Cut Saw

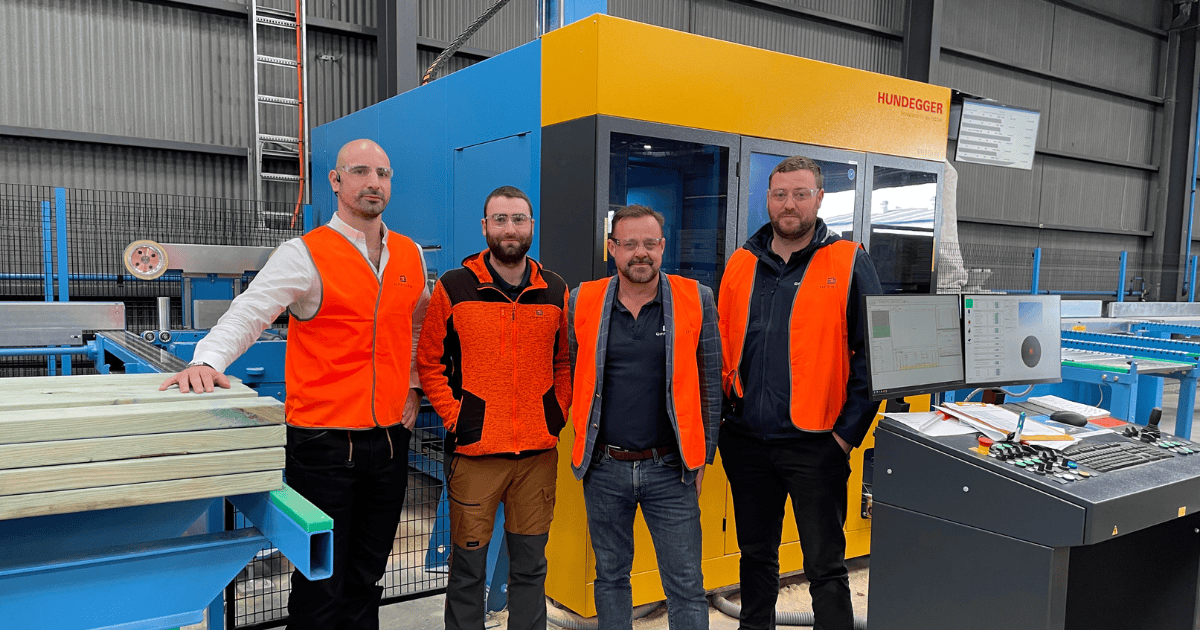

We’re excited to announce a major leap forward for OFFSITE and the entire WA timber building industry with our new Hundegger SC480 Speed Cut Saw. As the only machine of its kind in Western Australia and one of just two across the country, the SC480 represents a significant leap forward in OFFSITE’s mission to modernise and fast-track how buildings are delivered.

The saw is now fully operational at OFFSITE’s manufacturing facility, where it cuts all timber components for our prefabricated floor systems, wall frames and roof products. This machine is seriously fast. As a test during commissioning, it completed a live job six times faster compared to previous cutting methods. We expect this speed to increase even further as our team optimise their workflows.

A Smarter, More Efficient Way to Fabricate

One of the most immediate benefits of the SC480 is its ability to reduce timber waste to almost zero. Its advanced software precisely calculates and optimises every cut, ensuring we get the most out of our materials and produce minimal offcuts. The machine also significantly boosts efficiency by cutting two timber pieces at once, a process known as “stacking”, and by drilling floor cassettes.

The Hundegger has also transformed the way our carpentry team works. It has not only sped up timber cutting processes but also significantly reduced the margin for human error. Importantly, the technology has not replaced our skilled workforce. Instead, their work is more efficient, more accurate, and far less physically demanding.

The Future of Design and Construction in WA

From a design perspective, the new saw has opened up new possibilities by enabling construction techniques that would be too difficult or time-consuming to do manually. Our in-house design team can now export designs directly from 3D CAD/CAM software to the Hundegger software, eliminating the need to produce “shop files” required for manual cutting. The team can even see the entire job in 3D, before a single piece of timber is cut.

This investment is a natural step in OFFSITE’s long-term vision to redefine how homes and buildings are manufactured and installed in WA. With a focus on Design for Manufacture and Assembly (DfMA), we’re committed to delivering smarter, faster, and more scalable solutions to meet the growing demands of the local construction sector.

As the pressure on WA’s housing and construction industries continues to grow, OFFSITE is positioning itself as a key player in providing sustainable, high-efficiency solutions. The Hundegger SC480 is not just a machine; it’s where innovation and purpose come together to enhance manufacturing and production capabilities. It has truly turbocharged our manufacturing process, extending the possibilities for prefabricated timber built-form manufacturing in WA.